A 15ft Pram for Dinghy Cruising

20160601

20160701

20160711

20160801

20160901

20160915

20161201

20161215

20170107

20170113

20170114

20170119

20170120

20170122

20170123

20170131

20170208

20170219

20170220

20170221

20170224

20170225

20170318

20170328

20170329

20170408

20170409

20170417

20170420

20170421

20170422

20170423

20170424

20170425

20170426

20170427

20170501

20170509

20170521

20170525

<<

>>

20170219 |

|

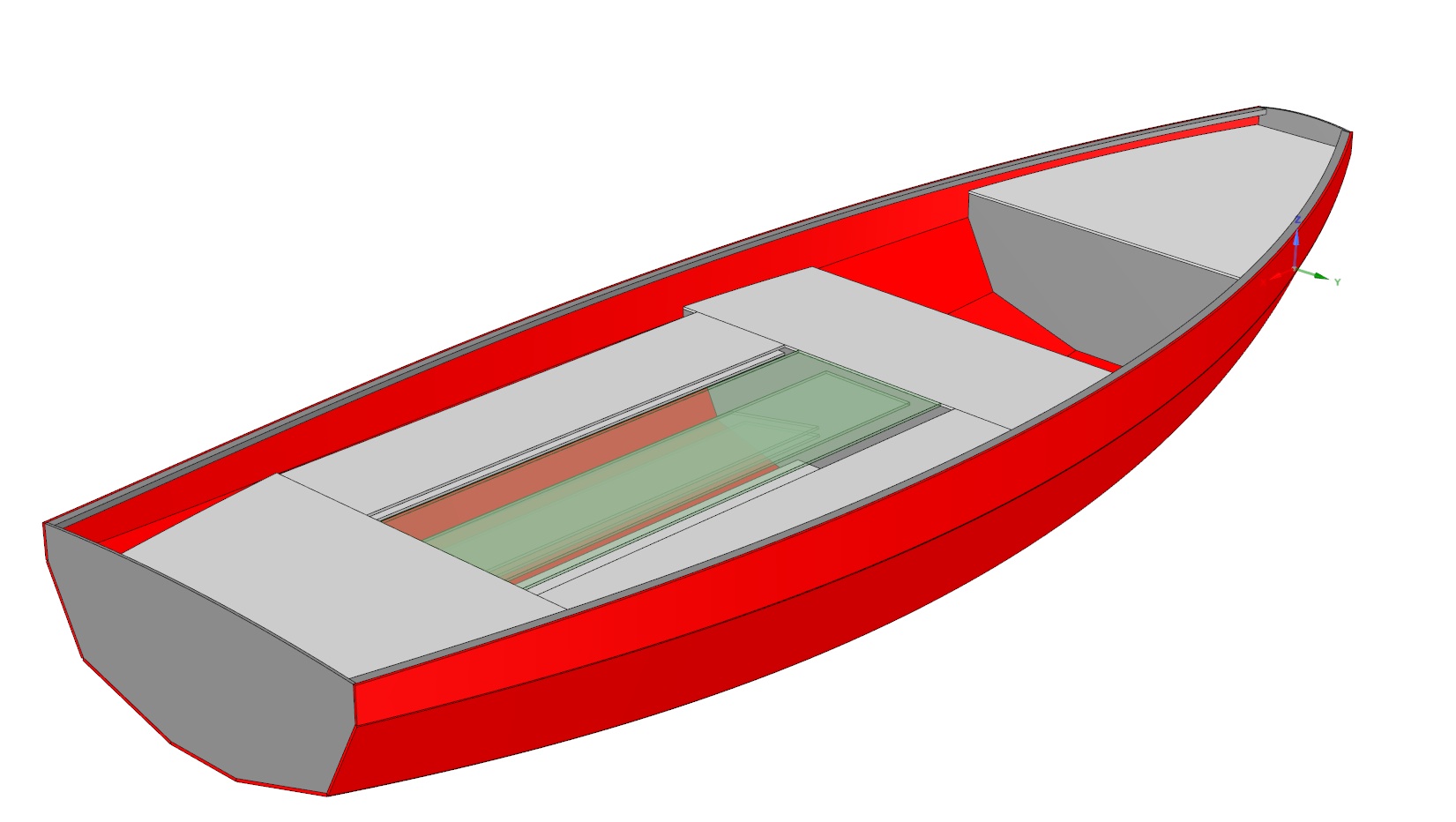

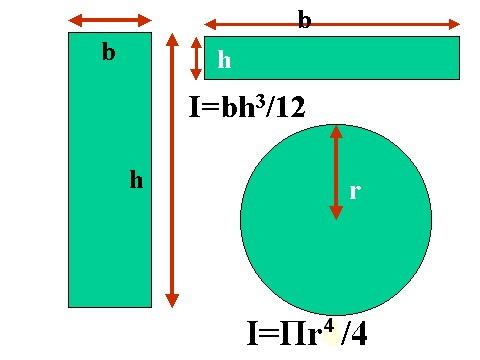

15-10-2024: Removed dead link to jimsboats.com In the Clinker Plywoord Boatbuilding Manual, Iain Oughtred proposes that the diameter of a solid unstayed round-sectioned wooden mast for a small boat should be 1:50 of LAD (length above deck). This is almost twice as big as the conventional mast of a racing dinghy. I guess the reason for this high value is that an unstayed mast should be extra stiff to cope with brutal downhaul needed in windy conditions. Working from this assumption, the mast of Hatseflats should have a diameter of 86mm based on 450cm LAD. The area will be app 58 cm2 (pi * r2). The area moment of inertia (I) is (r^4 * pi/4) = 43^4 * pi/4 = 2685120 mm4. Given a density of 0.5 the weight will be 2.9kg/m or 14.5kg for a solid untapered mast of 500cm. I like wood because it floats and is easy to work with. But nearly 15kgs for the mast alone is too much. 10-11kg would be acceptable but not much more. A solid square section of 75x75mm results in a marginally less stiff mast (I=bh^3/12). But with a weight of 14kg (2.81kg/m) this alternative is still too heavy.

A hollow wooden mast with the top half tapered to 70% should be a lot lighter.

This can be made with four tapered planks of 20mm around solid inserts.

For a concentric hollow square I = (BH^3 - bh^3)/12

The alternative is an untapered aluminium tube with a internal doubling in the lower 100cm.

The area moment of inertia of an annulus is (r2^4 - r1^4) * pi/4

Net weight is 5m * 2.04 = 10.2kg. With an inner sleeve for the lower 100cm, we arrive at 12.24kg. By using wood props in the ends we can even make it float. Links:

20170219_formulae.jpg Diagram by Michael Storer on the Wooden Boat Forum  20170219_tirrik3_03.jpg Tirrik built by De Zeeg. Alloy hull, alloy spars |