A 15ft Pram for Dinghy Cruising

20180625

20180626

20180627

20180628

20180629

20180902

20180915

20181014

20190208

20190422

20190510

20190511

20190512

20190525

20190601

20190803

20190804

20190805

20190807

20190811

20190819

20190820

20190821

20190822

20190823

20190828

20190908

20190922

20200216

20200603

20200612

20200712

20200718

20200719

20200727

20200822

20200905

20200910

20200911

20200912

20200913

20200920

20210305

20210509

20210724

20210905

20210912

20211003

20220430

20220508

20220603

20220618

20220821

20220828

20220904

20220911

20221009

20230423

20230520

20230528

20230625

20230805

20230806

20230810

20230903

20230906

20230910

20230911

20231001

20231008

20240423

20240515

20240603

20240614

20240623

20240710

20240714

20240716

20240720

20240723

20240725

20240726

20240727

20240730

20240908

20240915

20240929

20241007

20241019

20241021

20241110

20250420

20250421

20250422

20250428

20250504

20250505

20250622

20250630

20250707

20250716

20250717

20250718

20250719

20250720

20250721

20250724

20250725

20250825

20250907

20250910

<<

>>

20250630 |

New Oars for Hatseflats Part 1Why new oars?After 7 years of hard use my trusty Lahnakoski oars squeaked alarmingly with every stroke. My friend Joost said that the oarlocks were crying for lubrication. But it was too late. There was so much play between the oarlocks and their sockets that I had to replace them. I went to the Bootbouwer for a new set of bronze oarlocks and sockets but the bronze oar locks for the Lahnakoski oars were not available anymore. What to do?

Joost had a spare set of sockets and square oar locks that I could use.

The sockets were identical to the old ones so fitting them to the gunwales was a piece of cake.

The old oarlocks still fitted the new oarlocks but with some play.

So I had to use them carefully and lubricate them every time with leather grease.

Experimental oars!The easiest solution would have been to repurpose some carbon racing oars for Hatseflats. Racing oars already have collars for square oar locks. However, I am not a great fan of carbon fibre on small boats. You have to treat them really carefully and when they get damaged you end up with the worst possible splinters in your flesh. Joost likes carbon, but indicated that carbon is not so suitable for small and slow boats (sorry Hatseflats). Our small cruising dinghies don't plane and need to have some volume to stow all that gear, so the extra pull from carbon oars simply goes to waste. In order to row comfortably (at a slightly lower pace) you even want the oars to be a little more flexible than my Lahnakoski oars. The starting point for my new oars were the plans that Joost had created in 2018 for the Goat Island Skiff. The benefits of these oars were: slightly more flexible looms for more comfort and spoon blades for rowing with less effort. These plans had been used for years and been proved in practice. Job done, you would say.

However, Joost suggested a little experimentation to greatly simplify the building process.

The original plans required laminating the oar blades from two or three layers of 3mm veneer.

So apart from getting your hands on suitable okoume veneer there was the challenge of laminating the veneers

into the required shape for the spoon blade and carve out the corresponding hollow in the looms to a close fit.

More experimentsI started by creating new blades using an earlier experiment by Joost as a reference. With a length of 60cm and a width of 13cm my blades were going to be only slightly wider than my existing Lahnakoski oars. I did not need extra power but more comfort: I hoped that the spoon shape would mean less strokes and that the narrow blades would be comfortable in waves. Joost and I discussed the shaping of the looms, the end of which was that I would use the online drawings of the oars that Joost had made for the Goat Island Skiff. I used the building notes created by Joost to understand the building process and consulted the drawing for the correct dimensions. Only a couple of changes were required:

However, I inadvertently used the drawing from Duckworks made by Michael Storer. Stupid I know. Because the dimensions in the drawing were slightly different, I used my common sense to work out the dimensions myself. Only today I downloaded the proper drawings by Justin Wimpey. It looks like the dimension in the drawing are not so different from the ones I chose. Lets keep our fingers crossed! DimensionsUnaware that I was not using the correct drawing, I came up with the following dimensions:

Building the blades

Building the looms

Assembling looms and blades

Finishing work

Next steps

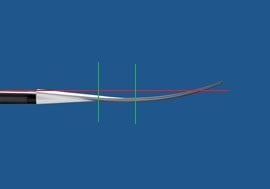

Inspiration for the scooped blade Flattened mould with widths at every 10cm. Flattened mould compared with Lahnakoski oar. Jig for new blades. New blade in the jig. New blade out of the jig. Using the router to create the handles. Handles roughly rounded. The new oars. New blades with 3 coats of epoxy. |